Warwick Acoustics Commercialises Automotive In-Car Audio Technology

Press Release

Following successful R&D and product development phases, Warwick Acoustics Ltd enters 2023 with an accelerating program to commercialise its revolutionary ElectroAcoustic Panel technology

- Warwick Acoustics is scaling rapidly, investing in industry-leading talent and facilities to support the substantial commercial pipeline that is developing

- • Warwick Acoustics is leading the ‘clean sound revolution’ to disrupt the $8 billion automotive in-car audio market with revolutionary ‘ElectroAcoustic Panels,’ which bring multiple benefits over conventional speaker technology

- • Warwick Acoustics is growing at 50% per year, underpinned by a number of key hires bringing industry-leading expertise in acoustic and automotive technology into the business and developing strong commercial relationships

- • Warwick Acoustics is strategically located in a purpose-built facility at the epicentre of the UK’s automotive sector at MIRA Technology Park, Warwickshire – Europe’s largest automotive R&D centre and proving ground

- • Company is investing in cutting-edge system design teams, product development facilities, testing laboratories focused on vehicle integration, and pilot production capabilities, as Warwick Acoustics progresses through this technology commercialisation phase.

- • Discover more: warwickacoustics.com/automotive

- • Media assets (Images of Warwick Acoustics MIRA Headquarters, their ElectroAcoustic speakers in a car and key personnel here: bit.ly/WarwickAcousticsMedia

Warwickshire, UK, 21 February 2023: Warwick Acoustics Ltd – a UK-based audio technology company, is well under way with commercialisation of its revolutionary Electrostatic Loudspeaker technology, following R&D and product development phases. Powered by a series of fully subscribed funding rounds, Warwick Acoustics is scaling rapidly, and investing in industry-leading talent, capability, and state-of-the-art facilities, to support the substantial commercial pipeline that is developing. The company is poised to disrupt the global $8 billion in-car audio sector while delivering a positive environmental impact.

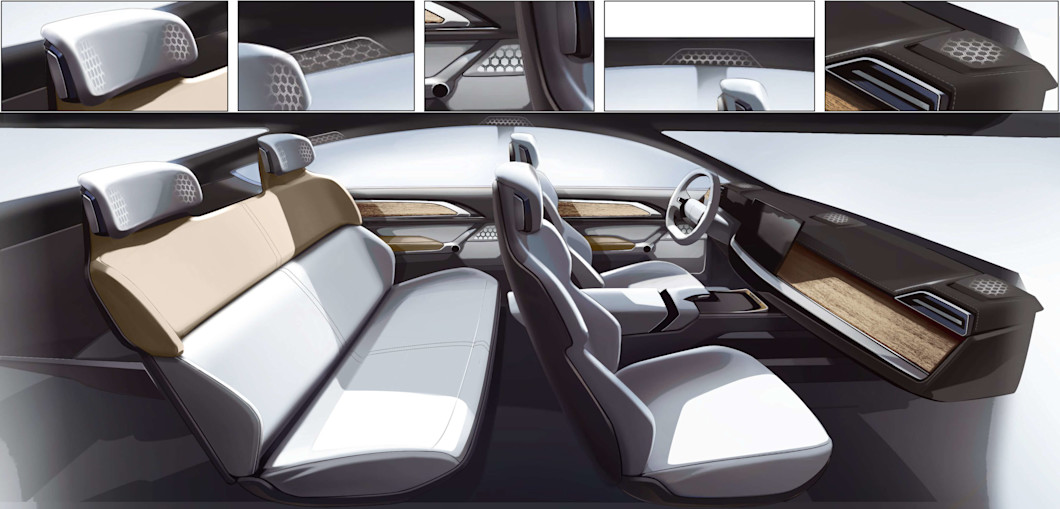

Warwick Acoustics’ is leading the ‘clean sound’ revolution, bringing significant benefits compared to the use of conventional audio technology. Like-for-like, ElectroAcoustic Panels are up to 90% lighter, whilst consuming up to 90% less power and offer significant interior design and packaging freedom. As automotive manufacturers (OEMs) set key sustainability objectives, including the decarbonisation of their supply bases, Warwick Acoustics’ ElectroAcoustic Panels offer breakthrough speaker solutions. The company’s use of 100% by mass upcycled and recyclable materials, provides OEMs with a key advantage to help them achieve their sustainability targets. Additionally, Warwick Acoustics’ ElectroAcoustic Panels do not use any unsustainable rare earth metals – something that the design of conventional speakers relies upon heavily.

To support the commercialisation phase, Warwick Acoustics has assembled a rapidly growing team of more than 40 global subject matter experts and leaders in mechanical, electrical, acoustical and systems engineering to redefine the science of electrostatic technology, the principles of in-car acoustic systems design, and manufacturing production techniques. The team brings experience in the in-car audio, technology start-up and automotive manufacturing expertise, from companies such as Sony, Bose, Harman Automotive, Jaguar Land Rover, McLaren Automotive, Meridian Audio and Google.

Over the next 12 months, Warwick Acoustics will be building upon significant commercial progress and several successful funding rounds to accelerate its growth trajectory. It is targeting an increase the size of its in-house team by a further 50% in 2023 to support the substantial commercial pipeline that is developing. This will include recruitment in a range of disciplines, with a particular focus on outstanding electrical and mechanical engineers with the skills, drive, and ambition to be part of a leading edge change movement towards sustainability within the industry.

The combination of elite talent and world-class electrostatic technology developed by Warwick Acoustics to date, has enabled the company to earn more than 30 global awards in the premium headphone ecosphere (https://warwickacoustics.com/reviews/). And this trend is destined to continue as the company expands into the global automotive sector.

With Warwick Acoustics’ ElectroAcoustic Panels now fully automotive-grade ready, the development of this new proprietary technology is perfectly timed to meet automotive OEMs’ rapid transition to electrification and life cycle sustainability.

Key Members of the Leadership Team

Mike Grant – Chief Executive Officer

As CEO of Warwick Acoustics, Mike Grant is a highly experienced business leader who has an exemplary track record of success scaling and commercialising global technology businesses, and start-ups. Grant’s achievements include introducing 3D graphics into the mobile phone industry, the creation of a 200m user chat community, and the development of a major mobile games publishing business. Grant’s initiatives have generated more than $600m in incremental value for shareholders. His strategic insight and business acumen is underpinned by a deep technical knowledge, which gives him an incredible foundation to lead an innovation powerhouse like Warwick Acoustics.

Ian Hubbard – Chief Commercial Officer

Ian Hubbard was hand-picked to lead the commercial team at Warwick Acoustics. His highly successful résumé in the global automotive acoustic sector includes playing a key strategic role in developing Sony’s global automotive business over a twenty-year period from scratch. Hubbard is an innovative global leader, with a proven pedigree of securing contracts that delivered annual revenues in excess of $200m and boosting bottom-line figures to double digits. He has consistently increased global market-share and boosted brand recognition and profit margins by creating highly effective, differentiated go-to-market product solutions.

Ben Lisle – Chief Technical Officer

Formerly Head of R&D at Automotive Supplier, Suprajit Ltd, which has 16 factories, producing 150 million parts for the majority of global OEMs , Ben has vast experience in integrating components and systems into vehicles. This knowledge is proving vital as Warwick Acoustics moves from developing the technology to vehicle integration. Ben explains the journey they are on, commenting: “The engineers we have here at our MIRA headquarters, are working at the cutting edge of audio systems, taking electrostatic technology that has never before been used in a vehicle, and transforming and refining it through a range of world class innovations to ensure that the performance, packaging and longevity meets the requirements of the world’s most prestigious OEMs. If you are a smart, forward-thinking electrical, mechanical or audio engineer who knows how to solve problems ahead of the curve, this is the kind of programme that you dream of delivering at least once in your career.”

Strengthened Board of Directors

As part of the company’s scale-up, Warwick Acoustics has also strengthened its Board with the appointment of Ian Harnett, a highly respected and longstanding senior executive in the automotive industry, as a Non-Executive Director. With an automotive career that spans nearly four decades, Harnett brings to Warwick Acoustics leading-edge expertise and high-level experience in automotive commercial negotiations, human resources expertise, and a proven track record in securing and bringing on-line automotive production facilities in a range of countries.

State-of-the-Art and Sustainable R&D and Production Facilities

Warwick Acoustics is headquartered at a new, high-tech, bespoke facility at MIRA Technology Park, Warwickshire – Europe’s largest automotive R&D centre and proving ground – at the very epicentre of the UK’s automotive industry.

Within Warwick Acoustics’ Product Development and Acoustic Testing Laboratory, the company’s engineers are spearheading the ‘clean sound’ revolution. In the new facility engineers have already begun installing ElectroAcoustic Panel based systems into demonstration vehicles, validating how in addition to the weight, efficiency and design freedom benefits, the acoustics of this unique approach that has been so successful in the headphone arena, translates perfectly into an automotive cabin environment.

In sympathy with the company’s environmental commitments, Warwick Acoustics’ facilities will soon take advantage of renewable energy supplied by MIRA Technology Park. The park’s new Energy Hub will supply on-site businesses with clean energy via a 7MW solar panel array and open a green refuelling forecourt providing hydrogen refuelling and electric vehicle charging.

Mike Grant, CEO of Warwick Acoustics, comments: “It is an exciting time for Warwick Acoustics as, following successful R&D and product development phases, we are well under way with the commercial introduction of audio systems based on our revolutionary ElectroAcoustic Panel technology. Following a series of fully subscribed funding rounds, we are scaling rapidly, investing in top talent and state-of-the-art facilities to support the substantial commercial pipeline that is developing.

Being able to secure hires such as Ian Hubbard to our leadership team and Ian Harnett to our Board of Directors is testament to the world class nature of our technology and the commercial potential of our solutions.

Our HQ at MIRA, a centre for leading automotive design and R&D teams, is proving invaluable as we attract the brightest engineering minds to work with exceptional automotive brands to integrate our revolutionary audio technology into vehicles.

Every automotive OEM is focussed on achieving Net Zero sustainability objectives. Warwick Acoustics can contribute to these goals with the world’s most sustainable audio solution – our proprietary ElectroAcoustic Panels that encompass the use of 100% by mass upcycled and recyclable materials.

Additionally, the lower energy consumption and weight of our solutions contribute materially to manufacturers goals of extending the range and performance of new electric models.

Our team can help OEMs with those targets, while at the same time enhancing, not compromising the customer experience.

With material and robust competitive advantages over our competitors in our ability to address all three of these key strategic OEM goals – sustainability, range extension and customer experience enhancement – I am confident that the business will continue to go from strength to strength for many years to come.”

ENDS